Screening bucket

RSB7 Models for excavators with operating weight from 1 to 50 ton.

Screening bucket with basket with interchangeable bolted grids, designed for the selection of material such as river bed, stony soils, aggregates from demolition or similar.

▶ Does not require drainage

▶ Basket with bolted grids (RSB 14 - 18 - 20 - 23)

▶ Easy and undemanding maintenance

▶ Maximum pressure valve

▶ Internal motor and hydraulics

▶ Bi-rotary basket

▶ Speed regulator in both directions

The ultimate expression of functionality and versatility. 0ne tool-multiple heads - Cut, crush, shear and pulverize. The MC Series feature an innovative “PRV” (Pressure Relief Valve) that protects the pulverizer from high pressure. Reinforced strength and durability from being manufactured with HARDOX 400. A reversed cylinder for ultimate rod protection. A fast-action valve. Interchangeable blades. An innovative interchangeable teeth system.

- Entirely made in HARDOX and STRENX.

- Boasts two large cylinders.

- Regenerative installation available in select models.

- Hydraulic Rotation comes standard.

- Continuous, precision 360° rotation in both directions thanks to an integrated hydraulic installations.

- Fast, accurate and efficient jaw positioning in and work condition.

- Ideal for excavators with long arms.

- Equipped with specialty clutch that permits a 360* rotation in both directions; ideal for excavators that do not have a rotation installation.

SHEET KIT

When precision and finesse are absolutely needed, this is the kit the job requires. From cutting sheets on the ground to demolishing metallic tanks, this kit delivers the confidence to get the job done error-free

CRUSHER KIT

Concrete structures = demolished.

CUTTER

Designed for tackling concrete and metallic structures during mixed demolitions.

SHEAR KIT

The tool for cutting ferrous materials, including structural steel, pipelines, tanks, sheets and ferrous carcasses.

UNIVERSAL KIT

Designed for primary and secondary demolition, simultaneously cuts metal bars and concrete.

PULVERIZER KIT

A go-to tool for secondary demolition: it separates rods from concrete.

6 models from 500 to 2000 liters and from 5 to 6 blades available

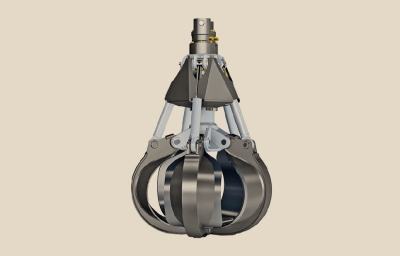

The Multi-Tine Grapple DP is the perfect tool in waste, wreckage and any type of glass, soil or sand material moving.

It comes with three types of jaws, open, semi- open and closed.

Those jaws kit offer the complete solution for any customer’s need. Thanks to its special geometry carefully designed, the DP is the perfect match for any industrial material handler or loader, having a superior loading capacity and an extreme resistance with an excellent and over performing capacity guaranteed.

▶ Built with high- strength steels and wear resistance

▶ Slim and robust structure

▶ High clamping force

▶ Reliable and with reduced maintenance

▶ Always protected reversed-principle cylinders

▶ Available in fixed version or with high performance 360° compact rotation.

12 Models for excavators with operating weight from 6 to 150 ton

MANUAL ADJUSTMENT OF THE NUMBER OF BLOWS (STANDARD)

Except for HP700S and HP1000S, all HP models have an adjustment of the blows, possible through the control valve placed on the cylinder of the hammer.

ADJUSTMENT OF THE OPERATING PRESSURE (STANDARD)

Thanks to a valve frontally placed on the distribution, it is possible to adjust the working pressure from 130 bar to 200 bar.

GREASING DEVICE (OPTIONAL)

The inner standard pipes allow direct greasing of the lower bush and the spacer, thereby improving the lasting of retainer pins and bush. Furthermore, the replacement of the greasing nipple with the tubes allows the possibility of greasing by controls in the cab or automatically, by vibration of the hammer.

DUST DEVICE (STANDARD)

A special device prevents the dust (for example, rock dust) from entering into the“chuck housing.” The presence of a“Air Filter”and a“non-return valve”into back head and in the chuck housing eliminates the“inflating”phenomenon, caused by movement up and down of the piston, thus creating an automatic effect of dust prevention.

7 Models for excavators with operating weight from 6 to 55 t

The RP Series - the specialists in the field of primary and secondary demolition.

Manufactured specifically with HARDOX 400 for maximum wear and tear resistance, the RP hydraulic rotating pulverizers come equipped with a regenerative circuit for ultra responsive opening and closing of their powerful jaws.

The RP series is further strengthened by a hydraulic rotation (360*) that allows maximum precision for pulverizer placement in any working condition.

▶ Featuring an innovative “PRV” (Pressure Relief Valve) that protects the pulverizer from high pressure.

▶ Reinforced strength and durability from being manufactured with HARDOX 400.

▶ A reversed cylinder for ultimate rod protection.

▶ Interchangeable blades.

▶ An innovative interchangeable teeth system.

9 Models for excavators with operating weight from 2 to 100 ton

Hydraulic shear for mini excavators and excavators. Perfect for the industrial demolition, for the cutting and the recovery of ferrous materials, like section bars, tanks, railway coaches, pipelines, ...

The shears are strong, compact and well built, engineered to shear iron parts in any shape and thickness, always in proportion to the attachment and the operating machine. The shearing section includes a fixed and a tilting claw, both fitted with interchangeable blades and a tip, in order to attack the metal sheets, which have high thickness. Made entirely from Hardox® and Strenx® steels, these shears deliver a superior amount of cutting force, ensuring a fast and efficient job every time.

▶ Continuous 360° rotation

▶ Speed Valve

▶ High cutting strength performances

▶ Fully-protected cylinder

▶ Adjusting spacer kit on moving jaw

▶ Interchangeable tip and reversible/interchangeable blades

9 Models for excavators with operating weight from 0.6 to 8.5 t.

MONOBLOC BODY WITHOUT TIE-RODS

The particular monobloc-body construction with metal heat-hardening treatment, gives the structure more resistance to the efforts of leverage at work. The breaker is manufactured in one piece and there are no tie rods.

N2 ENERGY SYSTEM

The hammer works with nitrogen inertial energy recovery. The gas gives much power to the machine and it also reduces stress on the arm of the excavator.

HIGH TIME CHARGE OF NITROGEN

In the past the hammers worked with gas energy recovery, required frequent refills. With this new range, using special sealing rings on the floating support, we have increased by 300% the residence time of the gas.

INSONORIZED

The particular monobloc-body construction, associated to the closed casing box , and the insertion of sound-absorbing material, has allowed to reach a very low working-noise levels.

PRESSURE

The SK series accepts very high values of back-pressure and very large range of calibration of the required oil flow, in order to facilitate the installation.

VISIBILITY

The SK series, with their streamline shape, allow good visibility during the work and allow to operate close to walls.

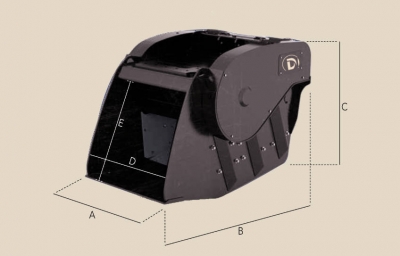

The DEMAL crusher bucket is ideal for your recycling needs about material coming from demolitions, quarries or natural stones. Built in HARDOX 400 ensures high production standards, reducing jaws wear. From FB250 model is available on request the electromagnet for metallic material separation (optional).

Crushing Bucket

The DEMAL crusher bucket is ideal for your recycling needs about material coming from demolitions, quarries or natural stones. Built in HARDOX 400 ensures high production standards, reducing jaws wear. From FB250 model is available on request the electromagnet for metallic material separation (optional).

5 models for excavators from 12 to 55 ton

- Adjustable size setting of Crushedmaterial from18mmto130mm.

- Eccentric-moving jaws system.

- Interchangeable anti-wear plow bolt inner plates (from FB300 HD)

- Interchangeable crushing jaw kit.

- Powerful Piston Motor

- Centralized greasing system

6 Models for excavators with operating weight from 1,5 to 31 ton

Selector grab for excavator and mini excavators from 1.5 up to 31 ton. This extremely versatile grab is widely employed for recycling, handling and demolition of non reinforced structures. It is used on construction sites for brick demolition, waste, wood, paper, aluminum and plastic handling, or where it is necessary to select or move material. It is considered a sort of “helping hand” of the construction site. Sturdy construction, high efficiency jaws movement, it features two jaws built in high tensile steel HB400 operated by an hydraulic cylinder and 360° hydraulic rotation.

Upper flange easy to match with any kind of coupler, either direct or quick.

▶ Interchangeable blades

▶ 360° Rotating

▶ 3 Models of jaws for any kind of handling use